Find High Quality Magnetic Separator, Permanent Wet Magnetic Separator, Wet Type Permanent Magnetic Separator on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

Model No.: CTB1018

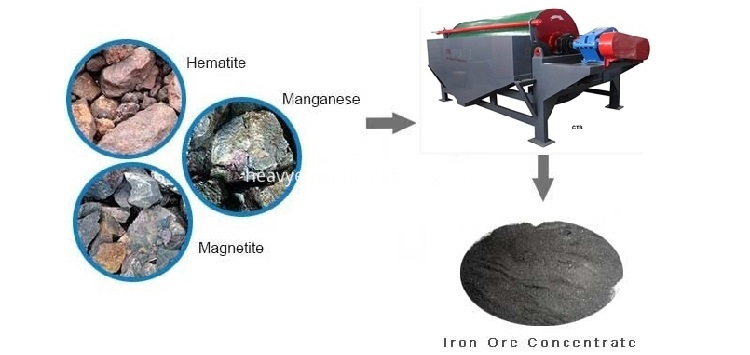

CTS (N, B) series high quality wet type permanent magnetic separator are suitable for wet separation of fine particles of strong magnetic minerals or removal of mixed strong magnetic minerals in non-magnetic minerals. The machine can continuously feed and drain ore, with large magnetic field depth, large working gap and high processing capacity.

The principle is that when the pulp enters the magnetic field area, the strong magnetic minerals are adsorbed on the surface of the cylinder, the weak magnetic and non-magnetic minerals are discharged, while the strong magnetic minerals adsorbed on the surface of the cylinder rotate with the cylinder, are taken out of the magnetic field area, and washed into the concentrate trough with flushing water to complete the separation operation.

The same cylinder can be equipped with three grooves, i. e. downstream groove (CTS), countercurrent groove (CTN) and semi-countercurrent groove (CTB), to meet different selection requirements.

The downstream groove is suitable for coarse separation and selection of ore size of 6-0mm.

The counter flow groove is suitable for coarse and selective ore size 0.6-0mm, and heavy medium recovery in the coal preparation industry.

Semi-counter-current trough is suitable for roughing and concentrating ores with particle size of 0.5-0 mm, especially for concentrating minerals with particle size of 0.15-0 mm.

The magnetic separator is a separating tank with a quantity of permeable stainless steel wool (or steel mesh) placed in the pinned solenoid coil. After the coil is excited, the permeable stainless steel wool is magnetized. The surface of the magnetic separator produces a highly uneven magnetic field, i.e. a high gradient magnetic field. When paramagnetic material passes through the steel wool in the separating tank, it will be subjected to an external addition. The magnetic force, which is proportional to the product of magnetic field and magnetic field gradient, is adsorbed on the surface of steel wool. Non-magnetic materials flow directly through the magnetic field, through non-magnetic Valves and Pipes, into the non-magnetic product trough. When the weak magnetic properties of the steel wool collection reach the degree (determined by the technological requirements), the ore is stopped. Disconnect the excitation power supply, flush the magnetic material, and the magnetic material flows into the magnetic product trough through the magnetic valve and pipeline. Then do the two homework, so circulate, go round and start again.

Magnetism separator is used to remove iron powder from reused powdery granules. High Quality Wet Type Permanent Magnetic Separator is widely used in resource recovery, wood industry, mining industry, kiln industry, chemistry, food and other workshops. High Quality Wet Type Permanent Magnetic Separator is suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with particle size less than 3 mm. It is also used for wet magnetic separation of coal, non-metallic ore, ilmenite and so on. The removal of iron from building materials and other materials is one of the widely used and versatile machines in the industry.

Model Diameter(mm) Length (mm) Magnetic induction Capacity(t/h) Popwer(kw) Weight(T) CTB612 Φ600 1200 MT≤100 10-20 1.1 1.5 CTB618 Φ600 1800 MT≤100 15-30 2.2 1.8 CTB718 Φ750 1800 MT≤120 25-45 3.0 2.2 CTB918 Φ900 1800 MT≤130 35-70 4.0 2.8 CTB1018 Φ1050 1800 MT≤135 40-75 5.5 4.3 CTB1024 Φ1050 2400 MT≤135 52-100 5.5 5.2 CTB1218 Φ1200 1800 MT≤135 47-90 5.5 5.0 CTB1224 Φ1200 2400 MT≤135 80-120 7.5 6.4

With programmable control, the whole production process is fully controlled and the process flow is easy to change.

Structural characteristics Wet Type Magnetic Separator For Mining

The whole device of magnetic separator consists of magnetic separator (host), coil cooling system, rectifier power supply, pneumatic control system and electromechanical control system.

The main machine includes magnet (coil, wrapped iron yoke), sorting box with magnetic medium and supporting structure, and material flow distribution system.

Coil cooling systems include cooling water piping, internal cooling and external cooling piping systems and heat exchangers.

Rectifier power supply includes dry rectifier transformer and SCR rectifier cabinet.

The pneumatic control system includes gas control valve, gas control cabinet and air compressor.

The control system includes manual and automatic operation control system, overpressure, pressure loss and overheat protection device of cooling system, interlocking operation of peripheral equipment, fault alarm and automatic shutdown system.

Purification of Industrial sewage and domestic sewage;

Product Categories : Beneficiation Equipment > Mineral Separator